When it comes to slip-and-fall prevention, there is no one-size-fits-all approach. That’s why for more than 30 years, Safeguard has offered customized solutions for anti-slip products that keep people safe while visually complementing any surface.

Our anti-slip products are built to last longer in the toughest environments on Earth, providing the best overall value on the market for reliable products designed to meet the specific slip-and-fall prevention needs of your business.

With experience serving more than 40 vertical markets, we are the industry experts, offering customized anti-slip solutions and installation services all over the world.

To find out if professional installation is right for your business, consider the following information.

Expert Anti-Slip Product Installers

Our wealth of experience in all industries has enabled Safeguard’s application specialists to gain insight into best practices based on environmental conditions and the installation methods of recommended products.

Each market, industry, location, and facility comes with unique requirements. In most cases, safety training is needed for each installation, in addition to background checks and drug screenings. Safeguard maintains necessary certifications for the industries we serve — for example, with the Mine Safety and Health Administration (MSHA) for working in mines — so that our installers are ready when customers need them.

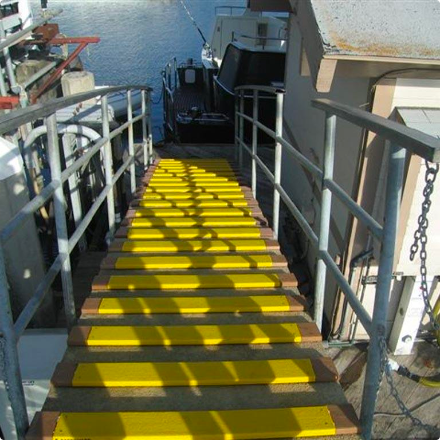

Paired with our global distribution network, Safeguard’s in-house team can install our anti-slip products nearly anywhere in the world. Recent installations range from a Columbus, Ohio facility where Safeguard installed 10 walkway covers, to an offshore installation where Safeguard installed 3,500 step covers while the drillship was en route from Malaysia to South Africa to minimize downtime in the shipyard.

As you can see, Safeguard installs in various locations and works with many different project sizes. It just needs to be cost effective for the customer. The average time frame for an installation varies with the complexity of the project. For example, the drillship install mentioned in the previous paragraph was a four-week project, while the Columbus facility walkway covers took four hours.

Safeguard has recently been contracted to install over 6,000 ladder rung covers at a major chemical production facility on the Gulf Coast of the U.S. Short-staffed, the customer chose Safeguard Technology to install the ladder rung covers so that he can utilize his staff for other plant projects.

Benefits of Installation

Clients choose the Safeguard installation team for many reasons, including their own staff shortages, the ease of relying on our expertise, and limiting the liability to one company for materials and installation.

The result is peace of mind that the project is done correctly. If unforeseen situations develop, Safeguard will make the necessary adjustments to ensure the installation is done properly. In addition, our experts are so well-versed in Safeguard products that they understand the pain points of an improper installation and work to achieve the customer’s satisfaction for both the product and the install.

While Safeguard anti-slip products are fairly straightforward to install by someone who is handy, a person without experience in this specific type of work may not properly install a product should they happen to encounter an issue. As a result, something that’s intended to be a safety enhancement could turn into a safety concern due to improper installation.

Cost Effectiveness

While Safeguard offers installation quotes on jobs (if requested), customers should consider cost effectiveness based on location, travel time, and project size to ensure the price of installation is commensurate with the overall cost of the project.

In general, installation is cost effective depending on the size of the job and distance from our installation teams.

In addition, a Safeguard installation is a good option when the customer doesn’t have the labor necessary to complete the job in a timely manner. For companies without a maintenance crew on staff, having Safeguard complete the install helps to make sure the project is done right, on time, and within specifications.

Holistic Approach

Safeguard installers work with the customer and our application specialists to assess the areas of concern and develop the best recommendation for a permanent solution. This holistic approach makes Safeguard unique among our competitors.

When planning an installation, the Safeguard team gathers all the necessary information to make the process as seamless as possible, including:

- The activity performed in the installation area

- Details about the work environment

- If training, permits, or certifications are required for installation

- If a spotter or escort is required to work onsite

- If additional personal protective equipment is required while on site

- If surface prep will be needed

- The hours of the day the installer can work

- If it’s possible to close off the work area

- The type of power supply access that is available

- Where installed equipment can be staged and stored

Take the Next Step

If you’re considering having anti-slip products installed in your facility or somewhere else to keep your workers safe, we recommend professional installation for all of the reasons above.

We understand that each application is unique and you want to get the most out of the anti-slip products you purchase. That’s why it’s best to rely on experts like us to ensure you select the right products and have them installed so they perform optimally.

Reach out to discuss your product and installation needs today.