First-rate anti-slip protection is required for a successful safety program. Fortunately, anti-slip effectiveness is not left to chance, but verified by independent laboratories. Review our performance on a variety of parameters below.

Independent Testing Results

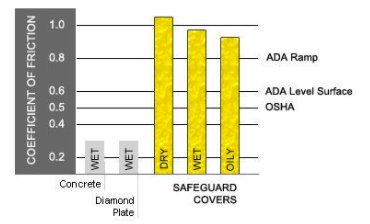

Coefficient of Friction

Coefficient of Friction (COF) is the measure of a product’s ability to provide safe traction and thereby prevent slips-and-falls.

Prior to 2006, ASTM International published standards for testing COF. Those standards were withdrawn because they referenced specific devices, the Brungraber Mark II and the English XL VIT. Although these are the most well-known and reliable devices for measuring COF, ASTM standards are meant to be neutral in regard to brand names. ASTM International now publishes F2508-11, the Standard Practice for Validation and Calibration of Walkway Tribometers Using Reference Surfaces, which contains evaluation criteria used to certify reliable testing devices. Both the Brungraber and the English devices have attained this certification.

We Exceed OSHA and ADA Standards

When SAFEGUARD® products were tested for Coefficient of Friction using the Brungraber Mark II testing device, the results showed a COF value nearly double OSHA’s 0.5 guideline and far exceeding the ADA’s recommended value of 0.6. Even when angled as an ADA access ramp, and in wet or oily conditions, our anti-slip surface greatly exceeds these guidelines.

Accelerated Weathering

Testing was performed on samples of both SAFEGUARD® Hi-Traction and SAFEGUARD® HiGlo-Traction samples.

Test Procedure

ASTM D4587 – Conducting Tests on Paint and Related Coatings and Materials Using a Fluorescent UV-Condensation Light- and Water-Exposure Apparatus

The method is a cyclic test comprised of 4 hours of exposure to ultraviolet light with the test specimens at 60°C followed by 4 hours of water condensation on the test specimens at 50°C. The fluorescent lamps closely simulate noon summer sunlight.

Test Results

The test period totaled 200 hours, approximately equivalent to 5 years normal exposure. The following changes took place:

| Measurement of lightness/darkness (L*) | small change |

| Tendency towards decreasing redness and increasing greenness (a*) | small decrease |

| Tendency towards increasing yellowness (b*) | slightly larger increase |

| Luminescence Retention (HiGlo-Traction Cover) | 100% after 158 hours 90% after 200 hours (slight yellowing of the epoxy) |

NYC Building Code- Law 26

| Photoluminescent Test Conditions | |

|---|---|

| Product Excitation | 4500K Fluorescent Light |

| Excitation Duration | 2 Hours |

| Illuminance on Surface | 2 Footcandles (21.6 lux) |

| Minimum Brightness Rating Required |

|---|

| 30.0 mcd/m2 at 10 minutes |

| 7.0 mcd/m2 at 60 minutes |

| 5.0 mcd/m2 at 90 minutes |

| mcd/m2 = millicandelas per square meter |

| SAFEGUARD® HiGlo-Traction Test Results | ||

|---|---|---|

| Minutes | Minimum Brightness Required | HiGlo-Traction Results |

| 10 | 30.0 mcd/m2 | 35.8 mcd/m2 |

| 60 | 7.0 | 7.7 |

| 90 | 5.0 | 5.0 |

Smoke and Flame Tests

Test results are summarized below:

| IMO RESOLUTIONS / ABS RULES for MOBILE OFFSHORE DRILLING UNITS/MARINE VESSELS | IMO FTPC Part 2 |

| Section 5.5.2: IMO Resolution A.653(16) – Recommendations on Improved Fire Test Procedures (Flame Spread) | Pass |

| Section 5.7.2: IMO Resolution MSC.61(67), Part 2 Smoke and Toxicity Test – IMO Fire Test Procedures Code (FTPC) | Pass |

| Federal Motor Vehicle Safety Standard No. 302 | Pass |

| ASTM E648 (Also NFPA 253 and FTM Standard 372) | |

| Average Critical Radiant Flux | 1.04 Watts/cm2 (FRP Covers) 0.93 Watts/cm2 (Vinyl Covers) |

| ASTM E662-01 (Also NFPA 258) | |

| Flaming | 761 |

| Non-Flaming | 398 |

| ASTM E84-03b | |

| Flame Spread Index | 25 |

Thermal Shock

Hi-Traction and HiGlo-Traction Covers were subjected to 20 cycles, with temperature ranging from -40°F to 150°F. Visual inspection for cracking or melting revealed no sign of damage.

Impact

Temperature of test-60°FEquipment used17 pound pendulumPotential energyApprox. 138 JoulesResultSlip resistant coating detached at point of impact only. No shattering occurred.

Wear Testing

Test Equipment“Bigfoot” Boot SimulatorNumber of cycles30,000Step ForceApprox. 400 pounds (182 kg)ResultLittle wear at end of test. Approximately 0.013 inch (0.33 mm) between worn and unworn sections of SAFEGUARD® Cover

Strength of Bond to Smooth Metal

Bond strength, SAFEGUARD® surface to smooth steel and aluminum: 800 – 1000 pounds per square inch

California’s Proposition 65

Dear Valued Customer,

Safeguard Technology would like to draw your attention to changes in regulations concerning California’s Proposition 65. Proposition 65 requires businesses to notify Californians about significant amounts of chemicals in the products they purchase, in their homes or workplaces, or that are released into the environment. This notice intends to provide you with a broad overview of the law and to inform you of the chemicals that can be found in our products. It is not meant to cover all aspects of your obligations, nor is it intended to provide legal advice. If you have not done so, please seek expert legal counsel on your obligations under Proposition 65.In summary, Proposition 65 requires businesses to provide “clear and reasonable” warning before knowingly and intentionally exposing anyone to a listed chemical, unless the business can show that the anticipated exposure level will not pose a significant risk of cancer or is significantly below levels observed to cause birth defects or other reproductive harm.Broadly speaking, Safeguard’s composite and steel products made with epoxy resins or vinyl ester resins, even after the article has been cured, could emit trace amounts of the following listed chemicals.

| Chemical | Risk |

| Carbon Black | Cancer |

| Ethylbenzene | Cancer |

| N-hexane | Reproductive Harm |

| Toluene | Reproductive Harm |

| Cobalt metal powder | Cancer |

| Epichlorohydrin | Cancer |

| Nickel metal | Cancer |

Under the provisions of Proposition 65, any consumer good made or sold in the State of California containing these chemicals requires a “warning” to consumers if use of the product could result in exposures above a “No Significant Risk Level” as determined by the State of California. The requirement to provide consumers the “clear and reasonable warning” went into effect on April 22, 2017. As a courtesy, we have provided the following warning language to include with our product in circumstances where the installation of our product might expose outside parties to the above listed chemicals (see Exhibit A). Failure to provide a Proposition 65 warning could subject you to enforcement actions for consumer goods sold or used in California. Detailed information regarding Proposition 65 can be obtained by visiting the State of California’s Proposition 65 website, http://oehha.ca.gov/proposition-65.

Safeguard Technology cannot give legal advice regarding your company’s compliance with Proposition 65 and strongly encourages you to seek expert legal counsel on this subject and its application for your particular business situation.

Sincerely,

William Kosinski

President