Wind energy is often celebrated for its sustainability and lower environmental impact. However, being good for the environment doesn’t necessarily make these sites any safer for workers. In fact, the wind sector includes several risks that employers and workers need to be aware of during construction and maintenance operations.

In this blog, we’ll take a closer look at the associated slip-and-fall risks associated with offshore and land-based wind energy development and how Safeguard Technology can help reduce those safety hazards.

Common Offshore & Onshore Wind Farm Slip-and-Fall Hazards

Wind turbines are tall structures, and throughout construction and maintenance efforts, workers may be required to climb ladders that place them hundreds of feet in the air. Fixed ladders inside wind turbine towers extend far beyond the height of a standard ladder, and when a fall does occur, workers may be more likely to suffer a serious injury or fatality.

The offshore work environment presents hazards not encountered on a land-based facility, including personnel transfers between vessels and wind turbines, and falls on the vessel or into water.

Personnel transfers are a necessary part of every visit to an offshore facility and pose potentially deadly risks. And when you combine fast-moving vessels, unpredictable weather conditions, and large bodies of water, you’re bound to experience slip-and-fall hazards. Other common slip-and-fall hazards on marine vessels include:

- Tripping Hazards: Some of the most common tripping hazards include service lines and hoses that run across decks, deck openings that aren’t properly closed or marked, access cuts not being properly closed or marked, and missing grates or plates

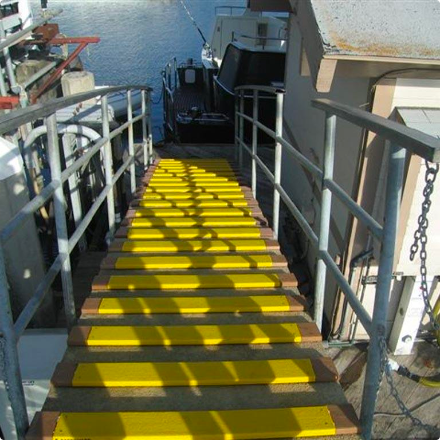

- Unmaintained Stairways and Ladders: If these areas are not properly maintained, the chance of a severe injury occurring on board will increase.

- Poor Lighting: Coupled with unsteady walkways and moisture, poor or dim lighting increases the chance of crew members getting hurt.

- Lack of Handrails, Guardrails, and Barriers: Rails and barriers, whether above or below deck, should be properly marked and available to hold onto during wet, slick conditions and rough, choppy waters.

Slip prevention is a top priority on-board and dockside for the maritime industry. Fortunately, there are anti-slip solutions available to help ensure the safety of marine vessel crew members and passengers.

Must-Have Anti-Slip Products for Wind Energy Production Sites

Ladder Rung Covers

Ladder rungs, especially those made from bar stock, are notorious safety hazards. The slick, small foot surface area present on ladder rungs can cause costly accidents and downtime for your business. Safeguard’s ladder rung covers significantly enhance safety in one of the most dangerous workspaces. Our ladder rung covers fit easily over any ladder rung with long-lasting durability, so that crew members can safely go from above deck to below deck with ease and efficiency. Maintenance personnel working on wind towers or nacelles need to safely climb between 100 and 300 feet from the ground level to reach the wind turbine’s mechanical drives, which makes safe, secure ladder rung traction crucial.

Step Covers

Any staircase on a marine vessel can become wet, icy, oily, and dirty due to the heavy machinery on-board and/or environmental conditions — that’s where anti-slip step covers come into play. Step covers provide excellent footing so that crew members and passengers can safely negotiate a vessel’s stairs with ease. The step covers even come pre-sized and pre-cut for easy installation.

Take the Next Step Toward Improving Safety — Offshore and Onshore

Seafarers and port managers alike understand the importance of maintaining a safe environment in these hazardous environments at sea and onshore. Our anti-slip covers exceed OSHA (Occupational Safety and Health Administration) regulations and have been protecting passengers and crews since 1992.

Our anti-slip products allow you to choose base layers of corrosion-resistant FRP, stainless steel, galvanized steel, or flexible PVC vinyl. These solid foundations are coated with our tough anti-slip surfaces to give you long-lasting protection where you need it most — even in the event of a fire.

Safeguard anti-slip covers with steel base material have been tested to the ISO 5659-2 protocol and found to comply with the two applicable International Maritime Organization (IMO) resolutions. When installed over compliant grating, anti-slip covers will not only protect your crew members from slips and falls, but they’ll also safeguard them from flames and toxic smoke in the case of a fire. Our anti-slip covers are the only products that comply with IMO resolutions cited in the ABS Rules for Building and Classing Mobile Offshore Drilling Units/Marine Vessels.

Request a consultation today and stop relying on products that aren’t designed for your wind energy production needs.