Anti-Slip Step Covers Installation at the Hides Gas Conditioning Plant

Safety, the Number One Priority

The Hides Gas Conditioning Plant is located in Papua New Guinea’s Hela Province. The plant processes up to one billion standard cubic feet of gas each day. More than 450 production staffers work around the clock every day of the year. It is out of concern for the safety of those workers that plant operator ExxonMobil took preventive action.

ExxonMobil’s PNGLNG website states, “Our safety philosophy is to prevent all incidents that can cause harm to our workers, the facilities, or the community and reflects our commitment to create a work environment where “Nobody Gets Hurt”.

In keeping with that policy, ExxonMobil recognized the need to neutralize the considerable slip-and-fall risk posed by metal surfaces when they become wet. They approached MONDIALE, a leading energy industry service provider, to supply and install anti slip measures on over 5,500 metal stairs.

Anti-Slip Step Cover Specifications

The solution needed to be resistant to the corrosive properties of oil and compatible with the tropical climate of Papua New Guinea, with a 10 year plus operational life expectancy.

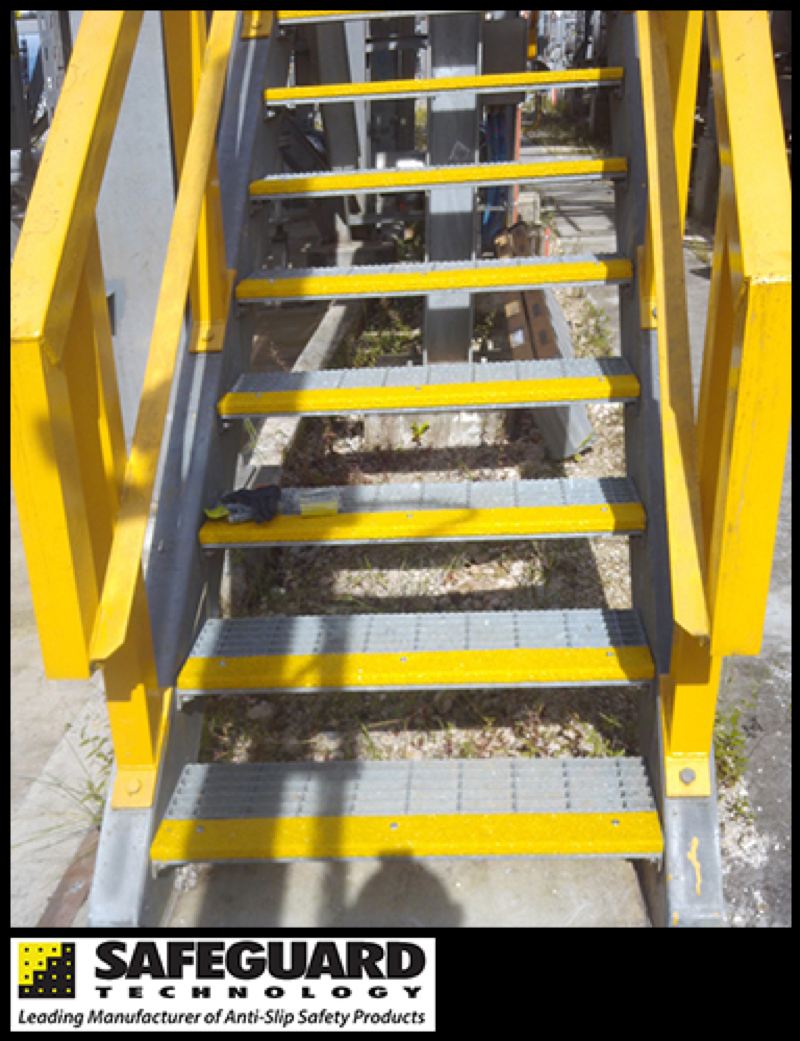

Safeguard® Hi-Traction® Step Covers were well-suited to the task.

MONDIALE’s engineering staff conducted a comprehensive survey of the various metal grating stairways across the facility. They encountered steps of varying widths and depths as well as varying nose profiles.

The original specification called for 1.2 mm AZ-150 COLORBOND® steel. This is essentially a coil coated steel. If a Colorbond part is scratched on the underside during a metal grating stairway installation, it will quickly corrode. Instead, hot dipped G90 galvanized steel was selected as the base material for the covers in this project since is not easily scratched. These covers also met the Class 1 fire and smoke requirement.

The order was placed with Safeguard Technology in Streetsboro, Ohio. The all-yellow step covers were coated in Offshore grit even though they were installed in an onshore facility. This ensured the proper grip for the wet conditions.

An order of thousands of step covers can take months to produce. In this case, four months later, the order was ready to go.

Shipment and the Extra Mile

The shipment left the manufacturer’s dock, neatly stacked and securely wrapped on three pallets, organized by installation areas with clearly marked destinations within the Hides plant. However, it arrived at the freight company in Chicago with one pallet broken and the other two badly damaged.

With the ocean shipment scheduled to occur in two days, time was short. It seemed as though the sailing date would be set back at least a week and the installation delayed. The parts needed to be unloaded, inspected, and repacked by someone familiar with the product.

To avoid delay, the manufacturer’s quality control manager, Lisa Talbott, immediately made plans to fly to Chicago and was there the next morning to assess the situation. Fortunately, the products were intact and could be repacked and made ready for the container’s ship-out the next day.

Installation and Results

Covers were applied to all the metal steps in the live process area as well as the condensate tanks. All steps in non-process areas were included as well. The majority of the step covers were made to the exact size needed, but MONDIALE opted to cut some in the on-site workshop outside the live process area in the plant.

The installation was completed in five weeks ‘without incident’ or ‘loss time injury’. ExxonMobil’s Hides Gas Conditioning Plant now meets their Global Safety Standards with regards to HSE compliance for stair treads. And the staff works confidently, knowing they have top-quality protection against slips-and-falls.

MONDIALE reports, “ExxonMobil are very happy with your stair noses.”