- Home

- Anti-Slip Product

- Anti-Slip Ladder Rung Covers

Anti-Slip Ladder Rung Covers

Our Hi-Traction® ladder rung covers deliver firm-footed traction from top to bottom, significantly enhancing safety in one of the most dangerous spaces: the slick, small foot surface area on ladder rungs.

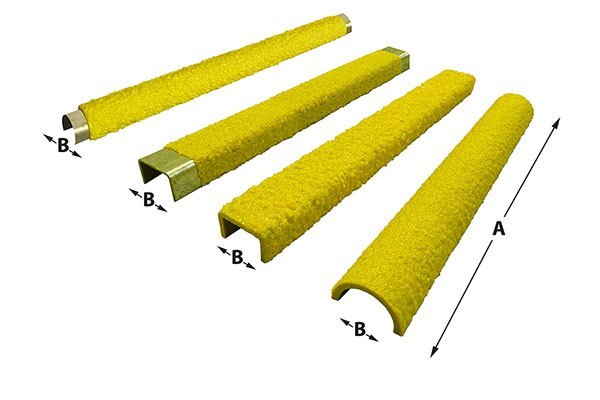

Safeguard’s two styles of anti-slip ladder rung covers fit easily over the rung, delivering complete, long-lasting performance in the world’s toughest indoor and outdoor environments. Our ladder rung covers:

- Come in channel-shaped and half-round styles

- Are made of FRP (fiberglass) and galvanized or stainless steel base

- Have adhesive, mechanical, or welded installation options

- Can be retrofitted in the field or specified as an OEM enhancement

Key Product Features

Key Product Features

Long-Lasting Grip

Product Specifications

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

Base Materials

Product Specifications

Choose from one of the following base materials of construction, or provide your own material for direct gritting:

- Pultruded fiberglass (FRP) is lightweight, impact-resistant, and cost-effective

- Galvanized steel 18 gauge (1.2 mm) G90 corrosion resistant

- Stainless steel 18 gauge (1.2 mm) #316 sanitary

- Direct grit – send us your OEM parts or your engineered drawings for fabrication, then gritting

Choose from the following base material shapes:

- Channel

- Half-round

- Angle

Available Sizes

Our range of lengths and diameters ensure you’ll get the perfect fit. It’s important to note that the length of the cover is generally up to 2″ shorter than the length of the ladder rung. If complete rung coverage is desired, make sure that no obstruction (e.g., a weld bead) will interfere with the seating of the rung cover.

Grit Options

Our ladder rung covers are available in five different grades of grit. Fine grade (commercial) is the standard choice for most ladder applications. Options include:

- Extra-coarse (offshore)

- Coarse (industrial)

- Fine (commercial)

- Extra-fine (residential)

- Super-fine (barefoot)

Color Options

The colors on this web page serve only as a visual guide for initial selection of color. Actual finished product color may vary slightly from the version shown on your monitor based on grit size (coarseness) as well as the base material of construction. To see the actual color, please request a product sample.

How to Place an Order

Our ladder rung covers are custom manufactured in the USA to meet your application requirements.

Contact us to request a quote, consultation, or sample. To place an order, please call 1-800-989-1695 or check availability in our online store.

How to Install

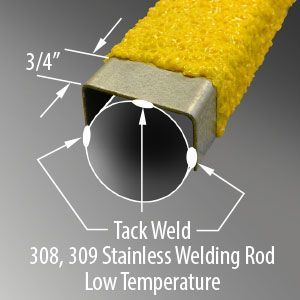

Most ladder rung covers are installed using Sikaflex adhesive. However, mechanical fasteners can be used (on large-diameter, channel-shaped hollow rungs). In the case of stainless or galvanized covers, tack-welding is an option.

Installation Using Adhesive

Adhesive is the only option when installing Safeguard FRP ladder rung covers. Tack-welding is the most popular method to install steel ladder rung covers, however, if hot work (e.g., welding or similar fire- or spark-producing operations) is not permitted, adhesive is also an option.

- Closely follow the surface preparation instructions for adhesive provided by Safeguard. Particular attention is necessary for carbon steel.

- Using fine-grade sandpaper, lightly abrade the underside of the cover. This will help in promoting the bond with the adhesive.

- Insert the cartridge of Sikaflex 252 into a caulking gun and puncture the seal to initiate flow. Follow instructions on cartridge specifying temperature and cure time.

- Start 1″ in from one end on the underside of the cover and apply a ¼” bead of adhesive the length of the cover, stopping 1″ from the opposite end.

- Hold the cover over the rung in the desired position.

- Firmly push the cover with adhesive onto the rung, taking care not to slide the cover.

Applying Ladder Rung Covers to Carbon Steel:

- Thoroughly clean steel rungs to remove any dirt, oil, grease, etc.

- Abrade to remove any rust.

- Apply a metal primer, followed by high-quality industrial coating that does not contain silicone or Teflon.

- When the topcoat is dry or cured, scuff lightly with sandpaper to remove gloss.

- Adhesive such as Sikaflex 252 can now be applied.

- Stainless and galvanized steel

- FRP half-round

- FRP channel

Installation Using Tack Welding or Screws

- Stainless and galvanized steel

- Mechanical fasteners