SAFEGUARD® Hi-Traction® Anti-Slip Covers Deliver Superior Performance Backed by Science

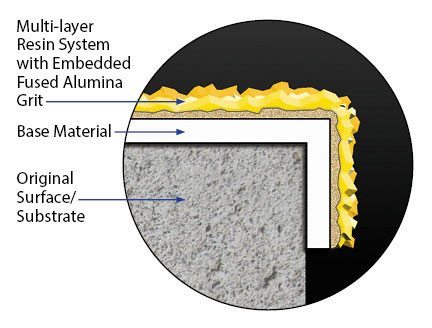

Our non-load bearing Covers are pre-fabricated to customer specifications for installation over existing steps, walkways, and ladder rungs – any area in need of dependable anti-slip protection. The Safeguard anti-slip surface is an engineered combination of epoxy, resin, and fused alumina aggregate which is bonded to a variety of base materials in a controlled environment.

Why fused alumina?

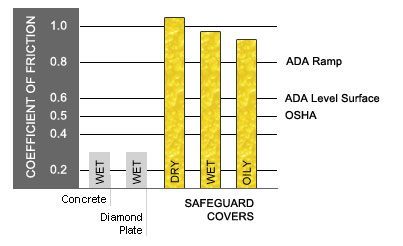

It is one of the hardest substances. When incorporated into our anti-slip surface, it creates hard, sharp edges that grip footwear, preventing slips even in adverse conditions. This adhesion can be measured for comparison, and standards have evolved to protect the public from false claims regarding anti-slip properties. The standards cite Coefficient of Friction (COF) values to indicate anti-slip effectiveness. A COF of 0.5 is a guideline for slip-resistance under ideal conditions. However, inclined surfaces such as ramps, and wet or oily environments require higher COF values to provide even minimal protection.

| Mohs Hardness Scale | |

|---|---|

| Diamond | 10.0 |

| Fused Alumina Used in Safeguard Products | 9.4 |

| Quartz/Silica Sand Most Anti-Slip Products Including Tapes | 6 - 7 |

Over the years, Safeguard has found a selection of base materials suitable for construction of our anti-slip Covers:

- 1/8” Pultruded Fiberglass (FRP)

- 1 mm Molded Fiberglass (FRP)

- Heavy-Duty Steel:

- #316 Stainless, 18 gauge (1.2 mm)

- G90 Galvanized, 18 gauge (1.2 mm)

- Flexible PVC Vinyl Sheeting

- Flexible Polymeric Geomembrane

- Your own base materials may be suitable for direct gritting

One is certain to meet the requirements of your application.