- Home

- Anti-Slip Product

- Anti-Slip Step Covers

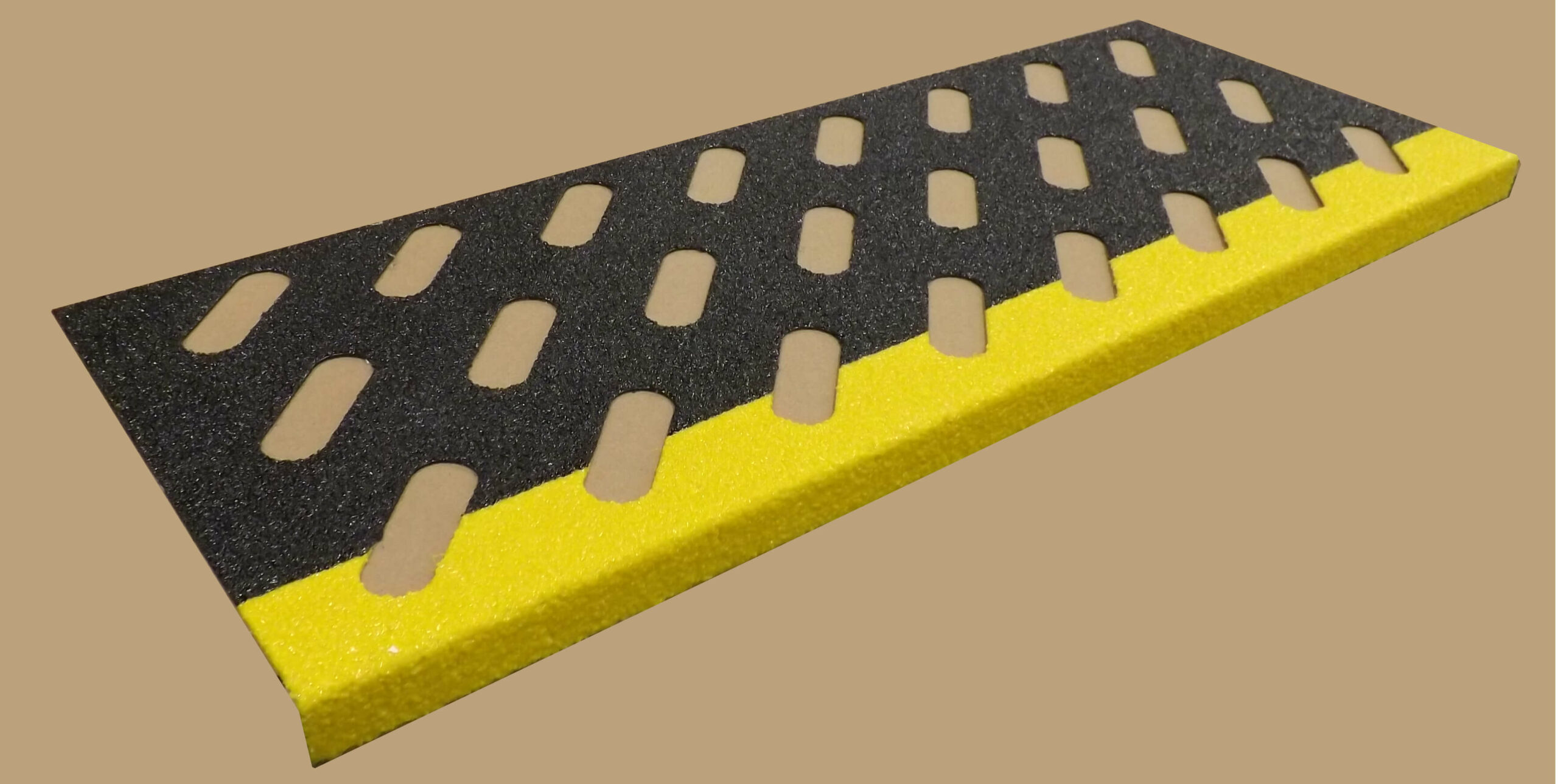

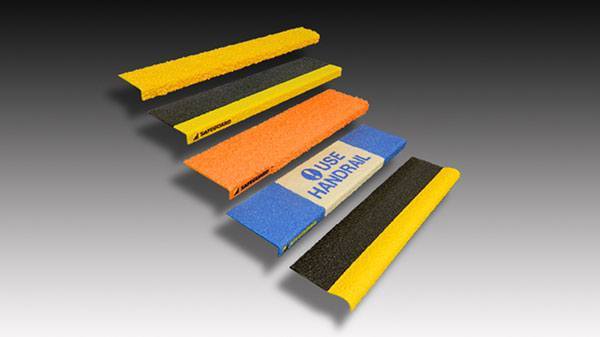

Anti-Slip Step Covers

Prevent costly slips and falls, especially on the leading edge of the stair, where most slips occur. Even in adverse conditions, when steps are wet, icy, or dirty, Safeguard Hi-Traction® and HiGlo-Traction® anti-slip step covers provide excellent footing, far exceeding OSHA standards. Our anti-slip step covers:

- Can be customized to ensure the right base material, grit, size, pass-through holes and colors are selected for your exact application

- Wrap the leading edge and cover the proper depth for foot traffic to eliminate slip and trip hazards

- Are fabricated to your specifications using a durable, non-load-bearing base of FRP fiberglass, galvanized or stainless steel

Key Product Features

Seamless Installation

Customizable Solutions

Product Specifications

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

THIS CONTENT IS DYNAMICALLY ADDED WITH JAVASCRIPT.

If you have Javascript turned off, this page won’t load as intended.

Base Materials

A selection of base materials and cover shapes are available to meet your application needs.

- ⅛” pultruded fiberglass (FRP) is lightweight, impact-resistant, and cost-effective

- Galvanized steel – 18 gauge (1.2 mm) G90 corrosion resistant

- Stainless steel – 18 gauge (1.2 mm) #316 sanitary

- Heavy-duty aluminum – ¼” thick and 18 gauge, 60/61 T marine grade is thick, rigid, and durable

- Direct gritting is available; send us your OEM parts or your engineered drawings for fabrication, then gritting

Pass-through Holes

- Pass-through holes are available on any of our base materials. The standard pattern is a round or oval pass-through hole, with additional patterns available upon request.

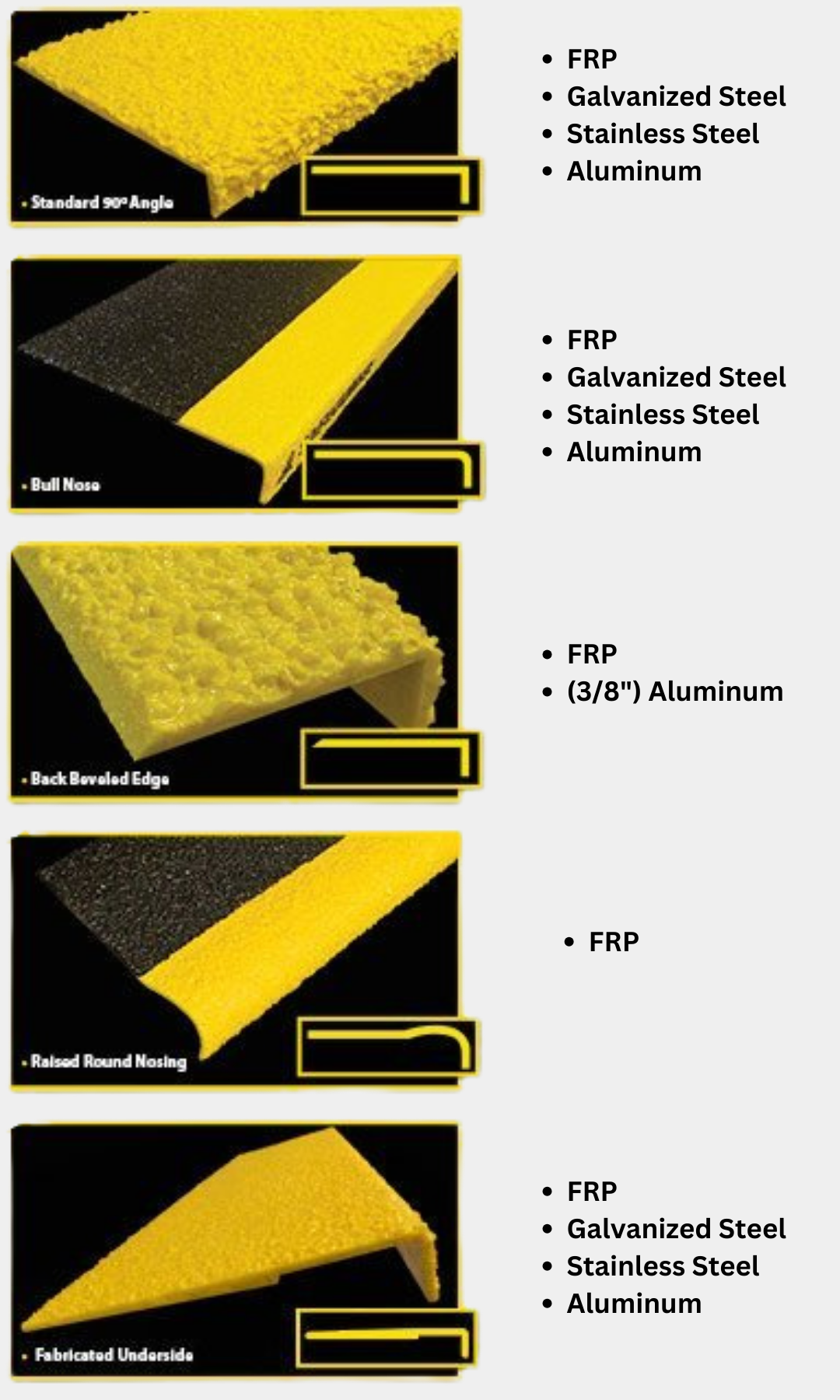

Cover Shape & Base Material

Available Sizes

Hi-Traction® and HiGlo-Traction® anti-slip step covers are designed to wrap over the leading edge with a standard 1″ vertical lip, thereby covering the radius where most slips occur.

It is not necessary to cover the entire step. When measuring the length of your step, leave some empty space on either side of the step cover to allow for seasonal expansion and contraction and for any irregularities that may exist from step to step.

In order to cover your steps to the proper depth, consider your foot traffic:

- What type of footwear is worn in the area?

- What substrate do you intend to cover?

- What is the condition of the existing stairs?

- How many steps are in the stairwell?

Maximum Capabilities:

Standard 90° FRP Covers

- Up to 10′ length and 15” deep

- Standard 1” lip (1.5” and 2” available)

Bull Nose Covers

- Up to 10′ length and 9” deep

- 1” lip

Steel and Aluminum Covers

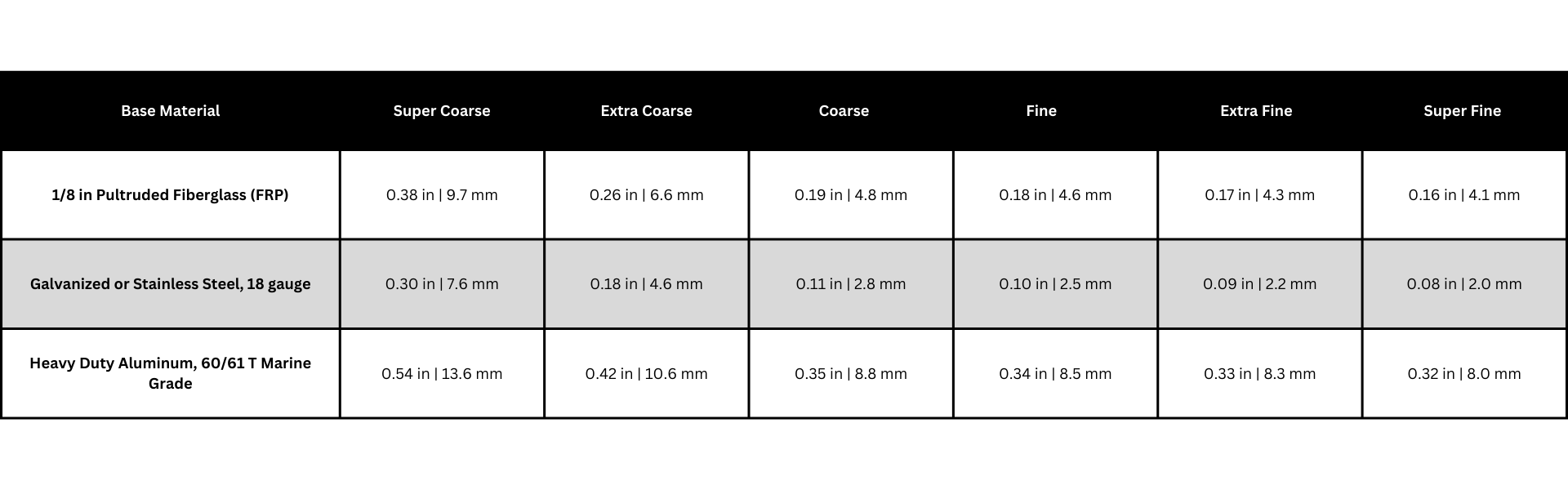

Grit Options

Our anti-slip step covers are available in a range of grit options:

Average Thickness of Finished Product

Color Options

Safeguard Hi-Traction® step covers are available in almost any color, including standard and safety colors, premium colors, glow-in-the-dark, and two-tone configurations.

View our full color resource here

Add Safety Messages and Logos

Warning messages, text, and logo graphics can be embedded into Safeguard step covers to last for the life of the product.

Combined with photoluminescent HiGlo-Traction® colors as background, the message is visible after dark and during power outages to provide safe egress/ingress during emergency evacuations.

Messages and logos can be easily translated into different languages to assist your guests and personnel.

How to Place an Order

Our anti-slip step covers are custom manufactured in the USA to meet your application requirements.

Contact us to request a quote, consultation, or sample. To place an order, please call 1-800-989-1695 or check availability in our online store.

How to Install

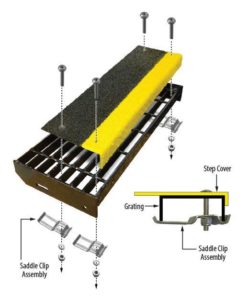

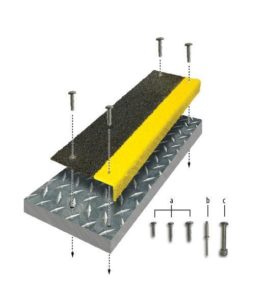

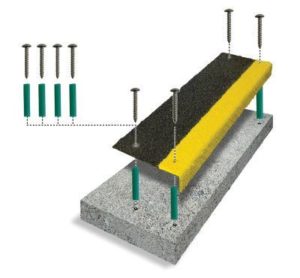

Safeguard step covers are easy to install on any surface: steel and composite grating, steel and aluminum plate, concrete, wood, and more.

How to Install With Mechanical Fasteners

| Step Cover Installation Over Grating Install using universal saddle clip assemblies with slotted truss head bolt, nut, and lock washer (all stainless steel). The number of saddle clip assemblies is directly influenced by the condition of the grating to be covered. New and good condition grating may not require as many saddle clip assemblies (good condition is considered flat/level and non-corroded). |

| Step Cover Installation Over Diamond/Checker Plate Install utilizing self-tapping or self-drilling (Tek) screws or rivets and low profile head, nuts, and bolts (depending on your particular application). Adhesive can be used in lieu of or in conjunction with mechanical fasteners. |

| Step Cover Installation Over Concrete Install using screws and masonry fasteners. Adhesive can be used in lieu of or in conjunction with mechanical fasteners. |

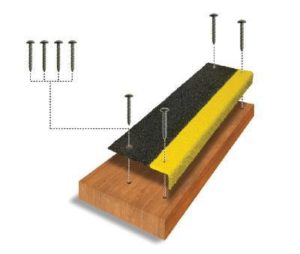

| Step Cover Installation Over Wood Install using 1 ½" standard type screws. Adhesive can be used in lieu of or in conjunction with mechanical fasteners. |

ATTENTION: Reduce the speed of your pneumatic air tools to prevent thread galling and bolt snapping while installing saddle clips. We recommend using a Torx screwdriver when installing to avoid head stripping. The use of a thread lubricant is also recommended to reduce heat and assist in the smooth installation of this product.

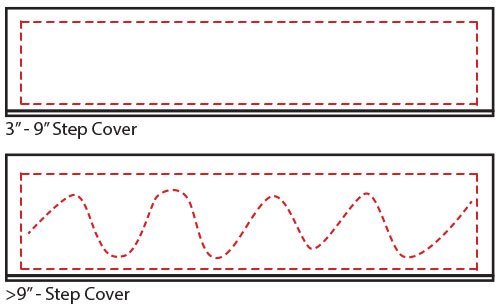

How to Install With Adhesive

Minimum adhesive usage is shown. Depending on the condition of the substrate, more can be applied or troweled. When using liquid adhesive, please refer to detailed installation and surface preparation instructions. Follow the lower pattern for maximum adhesion when installing over diamond plate, concrete, and wood.

Red indicates the pattern to follow when applying liquid adhesive.